Mxene: a New Family of Promising Hydrogen Storage Medium

Abstract

Ti3C2Tx belongs to the family of MXenes, 2D materials with an attractive combination of functional backdrop suitable for applications such as batteries, supercapacitors, and strain sensors. However, the fabrication of devices and functional coatings based on TiiiiC2Tx remains challenging as they are decumbent to chemical deposition by their oxidation to TiO2. In this paper, we examine the oxidation of Ti3CiiTx in air, liquid, and solid media via conductivity measurements to appraise the shelf life of TithreeC2Tx MXenes. The oxidation of Ti3C2Tx was observed in all the media used in this study, but it is fastest in liquid media and slowest in solid media (including polymer matrices). We as well bear witness that the conventional indicators of MXene oxidation, such every bit changes in color and colloidal stability, are non e'er reliable. Finally, we demonstrate the acceleration of oxidation under exposure to UV light.

Introduction

MXenes are 2nd materials consisting of Chiliad (early transitional metallic), X (carbon or nitrogen), and T (last groups). MXenes tin be represented with the general formula Grand n+i X north T x , where northward= one, 2, iii and x represents the number of terminal groups. They are usually derived from the parent MAX (or Grand n+1 AX n ) phases past the selective carving of the A chemical element (a grouping-xiii or -14 element). Out of over lxx known MAX phases with different compositions, only a few (~xx) take actually been experimentally converted into MXenes.1,2 The well-nigh common blazon of MXenes are titanium carbides (Ti3CiiT10), which are obtained from the parent titanium aluminum carbide (TiiiiAlC2) MAX stage past the removal of the aluminum layer by etching in hydrofluoric acid or in a mixture of HCl and fluoride salts; even so, there is a enquiry interest in pursuing etching without the use of fluoride ions.ane,3 Ti3C2Tx possesses high electrical conductivity, excellent electromagnetic shielding properties, and a loftier in-plane stiffness.4,v,6,7,8

The final groups (such every bit -F, -OH, and =O) of Ti3C2T10 MXenes are polar, making them hydrophilic and suitable for processing in water without the need of a dispersant. Aqueous Ti3C2Tx nanosheet dispersions can be assembled into films, polymer composites, or even into 3D crumpled morphologies.9,10,11 These MXene-based bulk materials have been utilized for hydrogen storage, antibacterial films, flexible electronics, h2o desalination, and absorption of heavy metals.12,13,14,fifteen,16 Additionally, because of their high conductivity and ease of processing, there is substantial research interest in utilizing these materials for batteries, supercapacitors, and strain sensors.8,17,xviii,19,twenty,21,22,23

Despite the promising properties of MXenes, questions well-nigh their chemical stability linger. Although a number of reports do not mention this, Ti3C2Tx MXenes are known to oxidize over time. This hampers the utility of Ti3C2Tx (and other MXenes) in numerous applications. Simply a few prior studies take explored this trouble, but methods for preventing or delaying the oxidation of MXenes are even so not well understood. Ghassemi et al. demonstrated the controlled oxidation of Ti3C2Tx MXenes under air to obtain TiO2 past varying the heating charge per unit, temperature range, and exposure time and showed that deadening heating rates cause the germination of rutile TiO2 particles whereas quick heating rates result in the formation of anatase TiO2 particles. The germination of TiO2 grains was observed through manual electron microscopy.24 Halim et al. observed oxidation on the surfaces of air-aged free-standing disks made by common cold pressing various multilayer MXene nanosheets (TiiiiC2Tx, TitwoCTten, TithreeCNTten, Nb2CTx, and Nb4C3Tten). The authors observed an increase in oxygen content on the surface with fourth dimension.25 Maleski et al. dispersed TithreeC2Tx in a wide range of organic solvents (polar protic, polar aprotic, and nonpolar) and analyzed the colloidal dispersion quality using Hildebrand and Hansen solubility theory. The authors noted that the colour of TithreeC2Tx in h2o dispersion changed from black to white, whereas that in organic solvent dispersions stayed black (Ti3C2Tten MXenes are generally black and TiO2 particles are white). They proposed that the lack of color modify indicates a slower oxidation rate in organic solvents when compared to water, suggesting the reaction of water molecules with TiiiiC2T10.26 Zhang et al. studied the degradation of MXene flakes in aqueous solutions and reported the post-obit: (i) the degradation of MXene flakes is size-dependent, (ii) the decreasing colloidal stability is correlated with MXene oxidation, and (iii) an oxidation-preventive storage method: storing MXene–h2o dispersions in hermetically sealed Argon-filled vials at 5 °C. The authors suggest that the dissolved oxygen in MXene dispersion plays a role in oxidation.27

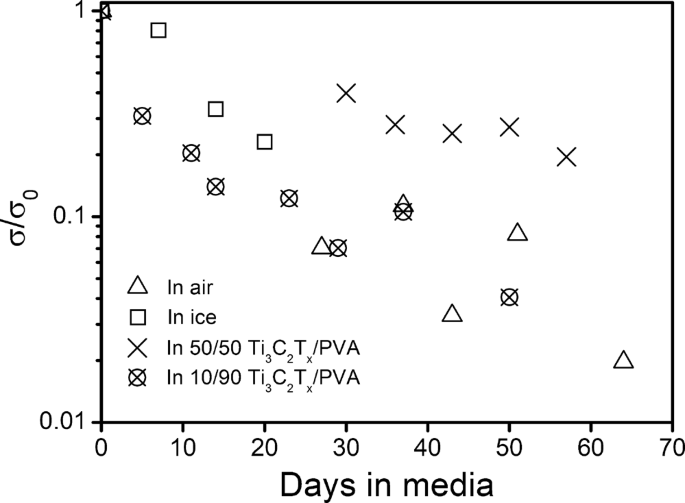

Despite these efforts, our current understanding of the comparative oxidation of MXenes in different media and conditions remains elusive. In this paper, we examine the oxidation of TithreeC2T10 in air, liquid (water, acetone, and acetonitrile), and solid (ice and polymer) media to sympathise how storage and/or dispersion media influence TithreeC2Tten oxidation processes. Under air, we detect a continual decrease in conductivity with a longer exposure time. In aqueous dispersions, we detect a abrupt decrease in electrical electrical conductivity while the dispersion retains its night color and colloidal stability even when the majority of it is oxidized. TithreeCiiTten dispersed in organic solvents (acetone and acetonitrile) had a abrupt drib in conductivity later on being aged xiv days in each medium. In air and solid media (frozen samples and polymer composites), the drib in conductivity was slower than that in liquid media.

Results

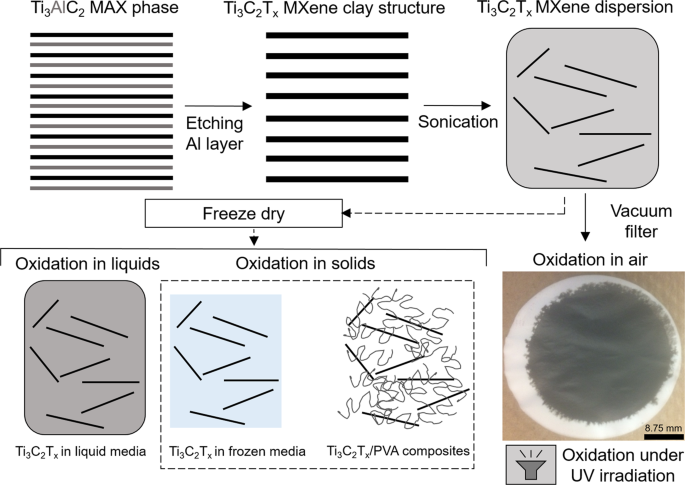

To prepare Ti3CiiTx MXene clay, we followed a previously reported procedure for etching the A layer from the parent TiiiiAlC2 (MAX phase) in a mixture of LiF and HCl for 45 h.11,28 Afterward carving, the TithreeC2Tx (MXene) dirt was washed with deionized (DI) water. The Ti3C2Tx powder was intercalated with dimethyl sulfoxide (DMSO) and then solvent exchanged to water. The TiiiiC2Tx MXene in h2o was bath sonicated and centrifuged, and the supernatant of dispersed, delaminated Ti3CiiT10 nanosheets was collected. These dispersions were freeze dried to obtain TithreeCtwoT10 nanosheets, which were used to set up samples past re-dispersing them in liquids (DI water, acetone, and acetonitrile) and in solid media (water ice and polymer matrices). The experimental procedure is schematically depicted in Fig. i.

An overview of the experimental process: after the synthesis of Ti3CiiTx MXene nanosheets from parent MAX phases, the samples were dispersed in various media

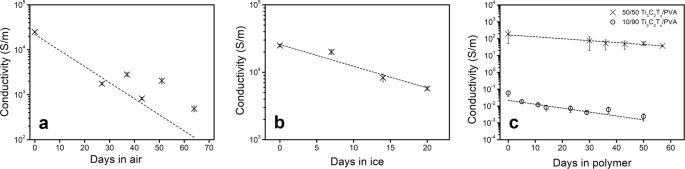

We used the electrical electrical conductivity of vacuum-filtered MXene films as an indicator of the degree of oxidation in air. Prior studies accept shown that an increased oxygen content in titanium oxide films leads to lower electrical conductivity; similar trends also exist for graphene conductivity and oxidation.29,30,31 Later delamination, aqueous dispersions of Ti3CtwoTx nanosheets were vacuum filtered to obtain a TithreeC2Tx nanosheet buckypaper. The buckypaper was vacuum stale overnight to remove any excess wet, and its electrical conductivity was measured to be 2.49 × 104 ± i.16 × ten3 S k-1; this was used equally a starting conductivity value for studying Ti3C2Tx oxidation in air and water. The buckypaper was kept at room temperature for the duration of the experiment, and its electrical conductivity was measured over time. Over a catamenia of 2 months, these TithreeCtwoTx vacuum-filtered films exposed to atmospheric air displayed a strong decrease in electrical conductivity (Fig. 2a). After 27 days of exposure, the conductivity was roughly seven% of the original value of 2.49 × 104 ± 1.16 × xiii S m-ane, suggesting rapid oxidation. The conductivity on the 64thursday day was 4.90 × ten2 S m-ane, which was less than ii% from the original 0thursday solar day measurement. This suggests a stiff decrease in electrical conductivity between the 0th and 27th mean solar day, and a weaker rate of decrease thereafter. In other words, the sample had more reactive sites in the early stages of the experiment such that the oxidation occurs much faster. Every bit the number of reactive sites decreases with fourth dimension, the oxidation charge per unit becomes slower. The fluctuations on the later days (27thursday day onwards) can exist attributed to changes in air humidity since humidity has been shown to affect the electrical conductivity of Ti3CiiTx MXenes.32

Conductivity vs fourth dimension measurements with error bars (standard deviations) for a Ti3CiiTx films in air, b films made from aged Ti3C2Tx dispersed in ice, and c Ti3C2Tten/PVA composite films. The subtract in conductivity is indicative of increasing oxidation

For our written report of oxidation in liquid media, 3 solvents (water, acetone, and acetonitrile) were used. We chose acetone and acetonitrile considering not-delaminated MXenes were observed to be the well-nigh resistant in these solvents (Supplementary Figs S5 and S6). The freeze-dried Ti3CtwoTx nanosheet powder was re-dispersed in all the three liquid solvents at a concentration of i mg ml−i using a vortex mixer. The freeze-dried pulverization dispersed back in h2o forming a colloidal dispersion just it did not disperse in acetone and acetonitrile. All the samples were prepared on the aforementioned twenty-four hour period.

We will first discuss the oxidation of TiiiiC2T10 in aqueous dispersions (Tabular array ane). Subsequently storing MXenes in water for i week, a portion of the dispersion was vacuum filtered into a pic and its electric conductivity was measured; the electrical conductivity of the MXene sample dropped from 2.49 × 10iv ± 1.sixteen × 103 Southward m–ane to 8.52 × ten3 ± ane.21 × 103 S m–one, or by more than 65% compared to the original sample. After 14 days, a portion of the remaining dispersion (supernatant) was once again vacuum filtered into a film and its electrical conductivity was measured. The conductivity of this MXene buckypaper was below the measurement threshold (<10three Due south thousand-1), suggesting a pregnant oxidation of TiiiiC2Tten. The results are in agreement with prior literature; Zhang et al. has as well reported the complete oxidation of their TithreeC2Tx MXene dispersion inside a span of 2 weeks.27 Their claim was based on a driblet in ultraviolet (UV) absorbance while ours is based on a drop in conductivity. Although our water–Ti3C2T10 system was (initially) a stable colloidal dispersion and black in color (Supplementary Fig. S1), UV–visible (UV–vis) measurements (Supplementary Fig. S2) revealed a massive driblet in concentration to 0.two mg ml−1 from the original one mg ml−1. The remaining stable colloidal particles had a ζ potential of −25.i mV, indicative of a stiff electrostatic repulsion between the dispersed particles. This suggests that the Ti3C2Tx colloidal particles may be oxidized simply not to the extent that they become colloidally unstable. X-ray photoelectron spectroscopy (XPS) assay revealed a high TiOtwo content of 55.8%, confirming oxidation (Supplementary Fig. S3). These data collectively suggest that Ti3C2Tx colloidal stability and black color are non always directly correlated with the degree of oxidation.26,27

In addition to investigating the chemical stability of Ti3CiiTx in aqueous dispersions, we also investigated the effects of humidity on the chemic stability of TithreeC2Tx buckypaper. The TithreeCtwoTx buckypaper samples were stored in three different relative humidity (RH) weather condition: 0, 50, and 80%. The conductivity of these samples was measured and the results are shown in Supplementary Fig. S7a. The samples stored in a dry out condition (RH 0%) maintained their conductivity well over a span of three weeks, while the samples stored in humid conditions experienced meaning drops in conductivity. The wettest sample kept in RH 80% experienced the highest drop in conductivity; the increase in TiOii content in this sample correlates well with the decrease in conductivity as shown in Supplementary Fig. S7b.

The freeze-dried TithreeCtwoTx powder formed a temporary stable colloidal dispersion in acetone and acetonitrile (Supplementary Fig. S8) after vortex mixing even though the Ti3C2T10 pulverization did sediment out after a few minutes. Vacuum-filtered films were prepared by vacuum filtering the temporary dispersions right later on vortex mixing (results in Table 1). Past day 14, Ti3C2Tx aged in all three of the solvents experienced a like drop in conductivity. However, by mean solar day 21, samples prepared from aging in each acetone and acetonitrile possessed a college conductivity than the sample prepared from water. This indicates that Ti3C2Tx oxidation in acetone and acetonitrile occurs at a lower rate than in water. The continued oxidation in acetone and acetonitrile can be attributed to their hygroscopicity. It is probable that they (acetone and acetonitrile) absorbed and retained h2o during the experiment. TithreeC2Tten MXenes also take a loftier affinity for water molecules, such that any h2o present in the atmosphere and/or the solvents would interact with the nanosheets and contribute to oxidation over time.33 Overall, our data suggest that storing MXenes in liquid media is conducive to oxidation.

Oxidation in ice was assessed by first dispersing TiiiiC2Tx in water and and then freezing it below 0 °C. The water ice samples were thawed past keeping the vials in room-temperature h2o for twenty min. Post thawing, the samples were vacuum filtered to obtain buckypaper; the buckypaper was vacuum dried overnight to remove whatsoever backlog moisture and then its electrical electrical conductivity was measured. The conductivity (as seen in Fig. 2b) compared to the original was, and 23% over 7, fourteen, and 21 days, respectively (in comparison, Zhang et al. reported a 43% drib in MXene concentration in the fresh sample after 25 days in their system in which the samples were kept at v °C and pressurized under Argon; presumably, the drop in concentration is the event of the MXenes sedimenting out). Overall, the frozen samples retained the electrical conductivity (inside the same lodge of magnitude) quite well compared to the samples in liquid medium, indicating slower oxidation. The slower oxidation tin can be attributed to the slower kinetics due to the solid media and lower temperature. Ti3C2Tx MXenes in solid media display slower oxidation rates. Even then, the oxidation process cannot exist entirely prevented.

TiiiiCtwoTx has also shown its potential every bit a filler in polymers with enhanced electrical electrical conductivity, mechanical performance, and electromagnetic interference shielding performance.5,half-dozen,10,xiv,34 However, no studies accept explored any subtract in performance of these materials due to Ti3C2Tx nanosheet oxidation. This issue is critical because of the potential commercial applications of these TiiiiC2T10/polymer composites. If MXene/polymer composites degrade over a short fourth dimension scale (1–iii weeks), and then the long-term utility of such materials becomes compromised, peculiarly for materials that rely on electric conductivity.

To assess the degradation of MXenes in polymer composites, we synthesized TiiiiC2Tx/polyvinyl booze (PVA) composites and measured the decrease in electrical conductivity with fourth dimension (Fig. 2c). PVA is a water-soluble polymer with a echo unit of [CH2CH(OH)] n . It is widely used commercially because of its hydrophilicity, biodegradability, and not-toxicity.35 The freeze-dried Ti3CtwoTx nanosheet powder was used to prepare these vacuum-filtered polymer composites at the post-obit ratios: (ane) 50–fifty wt% Ti3CtwoTx to PVA respectively and (ii) 10–90 wt% Ti3C2T10 to PVA respectively; both samples were kept under atmospheric conditions for the duration of the experiment. The conductivity of fifty–50 wt% Ti3C2Tten/PVA sample was roughly twoscore% of its original value on the 30th twenty-four hour period and xx% of the original value past the 57th day. The conductivity of x–90 wt% Ti3C2Tx/PVA sample was roughly seven% of the original value on the 29thursday 24-hour interval and 4% of the original value by the 50th day. Similar to the Ti3C2Tx film in air, there seems to exist a strong decrease in conductivity within the beginning 4 weeks, followed past a more gradual decrease in electrical conductivity thereafter (seen in detail in Fig. iii). This indicates a slowdown in the oxidation of Ti3CiiTx, most likely due to the decreasing number of reactive sites with time. Note that the two polymer composite samples (regardless of the amount of polymer) and the Ti3C2Tten moving-picture show in air sample follow a similar tendency. This suggests that the mechanism of oxidation in polymer composite is not affected by the amount of polymer, and the hydrophilic polymer does not form an effective protective barrier to prevent oxidation.

Chief curve for the normalized conductivity variation of films fabricated from MXenes dispersed in various media over time

These findings are consequent with the observations made on our recently reported layer-by-layer (LbL) films.23 Over a course of iv weeks, the absorbance of these MXene/PDAC LbL films decreased, suggesting oxidation (Supplementary Fig. S9).

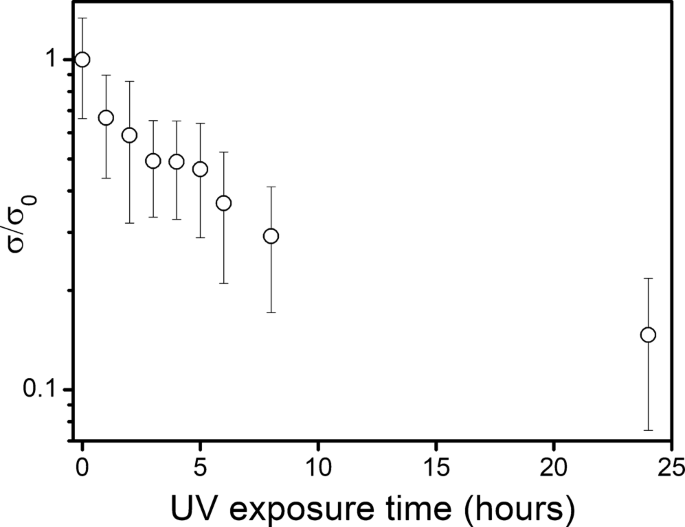

We also examined oxidation nether UV irradiation. In previous studies, Ti3C2Tx dispersions have demonstrated a strong absorbance in the wavelength range of 250–300 nm.xi Therefore, nosotros hypothesized that the exposure of Ti3C2Tx to UV light in this wavelength range would accelerate oxidation. Based on our data (Fig. 4 and Supplementary Table S1), there is a potent downtrend in conductivity with a longer UV time exposure, suggesting an increase in oxidation. It took but 24 h of UV exposure under atmospheric conditions to cause a conductivity loss of over > 85%, while a similar sample nether atmospheric conditions and stored in relative darkness experienced a conductivity loss of over > 85% in 27 days. This has serious implications for Ti3C2Tx MXene composites made from UV-cured polymers; UV curing may dethrone TiiiiCtwoTx MXenes within the monomer.

Modify in electrical conductivity of MXene film with increasing UV exposure time

We argue that there are two reasons for the accelerated Ti3C2T10 oxidation nether UV light. The beginning is the transformation of UV light to rut, leading to an increased oxidation kinetics. It has been demonstrated that Ti3C2Tten MXenes can absorb light and convert it to heat with almost 100% efficiency.36 The second is the generation of radicals nether UV light that may set on the Ti3C2Tx surface, causing further oxidation. We surmise that the UV light interacts with the TiOtwo causing O∙ and OH∙ radical formation from the oxygen and moisture present in the environment.37 With longer UV exposure times, more radicals were generated, leading to more oxidation. Even and so, more experiments need to exist done to properly appraise UV furnishings on TithreeC2Tten oxidation.

Discussion

We assessed Ti3C2Tx oxidation behavior in air, liquid, and solid media; we observed that the oxidation is the slowest in solid media and the fastest in liquid media. In water, TiiiiC2Tx oxidizes inside 2 weeks, and the data suggest that the dispersion's blackness color and colloidal stability are not reliable indicators of oxidation, contrary to the prior reports. From a storage perspective, TithreeC2Tx can be preserved in water ice (and to a lesser extent in some organic solvents) to decrease oxidation or freeze dried to grade a re-dispersible powder. Ti3C2Tx composites, regardless of the corporeality of polymer, display similar profiles in terms of decrease in electrical conductivity, suggesting that the polymer does not act as a barrier to decrease oxidation. Additionally, nosotros take found that exposure to UV accelerates oxidation in TiiiiC2T10 films. Nosotros anticipate that this will be 1 of the many studies needed within the MXene customs to understand and prevent their oxidation and allow for their longer shelf life and reliable functional properties.

Methods

Synthesis of Ti3AlC2 MAX phase

Commercial Ti (average particle size 44 μm, 99.5% purity), Al (average particle size 44μm, 99.5% purity), and TiC powders (boilerplate particle size 2–3 μm, 99.v% purity) (all from Alfa Aesar, MA, U.s.) were used as starting raw materials to synthesize Ti3AlC2 MAX phase. To set homogeneous powder mixtures, Ti, Al, and TiC powders were first weighed to accomplish Ti:Al:C = iii.0:1.2:ane.viii ratio and mixed together using ball milling with zirconia chaplet in a glass jar at a speed of 300 rpm for 24 h. Then, the bulk high-purity Ti3AlC2 samples were sintered at a temperature of 1510 °C for 15 min with a loading of l MPa using Pulsed Electric current Organization (PECS). To fabricate loftier-purity Ti3AlC2 pulverisation, the PECSed sample was beginning drill milled and sieved to obtain powder with particle sizes below 44 µm.11

Synthesis of Ti3C2T10 MXene clay

TithreeC2Tx MXene clay was synthesized by etching Al from the Ti3AlCtwo phase using the technique described by Ghidiu et al.38 Concentrated hydrochloric acid (HCl, ACS reagent, 37% w/w; Sigma-Aldrich) was diluted with DI water to obtain xxx ml of 6 1000 HCl solution. This solution was transferred to a polypropylene (PP) beaker and ane.98 g of lithium fluoride (LiF, 98 + % purity; Alfa Aesar) was added to it. This dispersion was stirred for v min using a polytetrafluoroethylene magnetic stirrer at room temperature. Ti3AlCii MAX phase powder was slowly added to the HCl + LiF solution to forestall overheating as the reaction is exothermic. The PP beaker was capped to prevent the evaporation of h2o, and a pigsty was fabricated in the cap to avert the buildup of hydrogen gas. The reaction mixture was stirred at twoscore °C for about 45 h. The slurry production was centrifuged and washed with DI water to remove the unreacted hydrofluoric acrid and h2o-soluble salts. This washing procedure was repeated until the pH of the filtrate reached a value of about 5. The reaction product was collected at the bottom of the PP centrifuge tubes and was extracted as TithreeC2Tx MXene clay.11

Intercalation and delamination of Ti3C2Tx MXene clay

TithreeC2T10 MXene clay was intercalated with DMSO and eventually bath sonicated to obtain an aqueous dispersion of delaminated Ti3CiiTten MXenes following the procedure described in more detail past Mashtalir et al.seven DMSO (ReagentPlus, >99.v%; Sigma-Aldrich) was added to Ti3CiiTx MXene to form a sixty mg/ml suspension followed by nigh 18 h of stirring at room temperature. After intercalation, the excess DMSO was removed by several cycles of washing with DI water and centrifugation at 5000 rpm for four h. The suspension of intercalated Ti3C2Tx MXene clay in deionized water was bathroom sonicated for one h at room temperature followed by centrifugation at 3500 rpm for 1 h to split the heavier components.xi

Training of Ti3CtwoT10 vacuum-filtered film before freeze drying

After centrifugation, the supernatant was collected and vacuum filtered on a polytetrafluoroethylene membrane (0.45-µm pore size). The vacuum-filtered film was then vacuum dried overnight. This was the reference for all vacuum-filtered samples.

Freeze drying Ti3C2Tx nanosheets

After centrifugation, the collected supernatant was stored in a freezer (<0 °C) and then freeze dried (Labconco FreeZone) for 3 days to obtain Ti3C2Tten nanosheet powder.

TithreeC2Tx in organic solvent

The freeze-dried Ti3C2Tx pulverisation was added to 100 ml of acetone and acetonitrile at a concentration of i mg ml−1. TiiiiC2Tx powder in both the organic solvents was mixed with the assistance of a vortex mixer to form a temporary colloidal solution as all the Ti3C2Tx powder sedimented out later on a few minutes (for both acetone and acetonitrile). Therefore, to obtain a vacuum-filtered film, the solution was vacuum filtered right afterwards vortex mixing. The vacuum-filtered moving-picture show was then vacuum dried (to eliminate any wet) before the electrical conductivity was measured.

TiiiiC2Tten in water

The Ti3CtwoTten pulverisation (concentration of ane mg ml−1) was added to 100 ml of h2o and shaken with the help of a vortex mixer; the powder dispersed upon contact with h2o. X milliliters of the sample was fatigued out every week to prepare a vacuum-filtered moving picture. The film was and then vacuum dried overnight (room temperature) before its electric conductivity was measured.

Ti3C2Tx in ice

Forty milliliters from the water dispersion was drawn out and separated into four 10 ml samples. The iv samples were stored in the freezer to freeze the samples. To prepare a film to mensurate the electrical electrical conductivity, each sample was thawed by submerging the sample container in room-temperature water. After thawing, the sample was vacuum filtered to obtain a flick; the film was then vacuum dried overnight before its conductivity was measured.

TithreeCiiTx in polymers

TithreeC2Tx powder and PVA (i sample with 50–50wt% and another with ten–ninety wt%, respectively, with a full solid concentration of 1 mg ml−1) were bath sonicated for 15 min and then vacuum filtered to obtain a polymer composite moving-picture show. These films were vacuum dried overnight (room temperature) before their electrical conductivity was measured.

UV oxidation

TiiiiC2Tx dispersion was vacuum filtered for xxx min to obtain a buckypaper movie so it was vacuum oven stale overnight to remove all moisture. Conductivity of the Ti3C2Tx motion picture was measured before and after UV exposure. All the experiments were done under dark housing, where the only source of light the sample was exposed to was the UV lamp (254 nm, 4W, 0.16A).

Characterization

Conductivity measurements were done using 4-Betoken Resistivity Probe powered by Keithley 2000, 6221, and ii 6514s. XPS measurements were conducted using Omnicron XPS. Zeta potential was measured using Malvern Zetasizer ZS90. UV–vis measurements were done using Shimadzu UV−vis 2550.

Data availability

All the data generated and analyzed in this report are included in this manuscript and its supplementary data file. Additional details are available upon asking.

References

-

Naguib, 1000. et al. Two-Dimensional nanocrystals produced by exfoliation of TithreeAlC2. Adv. Mater. 23, 4248–4253 (2011).

-

Anasori, B. et al. Two-Dimensional, Ordered, Double Transition Metals Carbides (MXenes). ACS Nano ix, 9507–9516 (2015).

-

Sunday, W. et al. Electrochemical etching of Ti2AlC to Ti2CTx (MXene) in low-concentration hydrochloric acid solution. J. Mater. Chem. A v, 21663–21668 (2017).

-

Naguib, M. et al. Two-Dimensional Transition Metallic Carbides. ACS Nano 6, 1322–1331 (2012).

-

Shahzad, F. et al. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 353, 1137–1140 (2016).

-

Han, M. et al. Ti3Ctwo MXenes with Modified Surface for High-Performance Electromagnetic Absorption and Shielding in the Ten-Band. ACS Appl. Mater. & Interfaces eight, 21011–21019 (2016).

-

Mashtalir, O.et al. Intercalation and delamination of layered carbides and carbonitrides. Nat. Commun. four, 1716 https://www.nature.com/articles/ncomms2664#supplementary-data (2013).

-

Er, D., Li, J., Naguib, M., Gogotsi, Y. & Shenoy, Five. B. Ti3C2 MXene equally a high capacity electrode cloth for metallic (Li, Na, Yard, Ca) ion batteries. ACS Appl. Mater. & Interfaces 6, 11173–11179 (2014).

-

Hu, One thousand. et al. Cocky-assembled Ti3CiiTx MXene picture show with high gravimetric capacitance. Chem. Commun. 51, 13531–13533 (2015).

-

Zhang, H. et al. Preparation, mechanical and anti-friction performance of MXene/polymer composites. Mater. & Des. 92, 682–689 (2016).

-

Shah, S. A. et al. Template-free 3D titanium carbide (Ti3CiiTx) MXene particles crumpled past capillary forces. Chem. Commun. 53, 400–403 (2017).

-

Hu, Q. et al. MXene: A New Family of Promising Hydrogen Storage Medium. J. Phys. Chem. A 117, 14253–14260 (2013).

-

Rasool, K. et al. Antibacterial Activity of TiiiiC2Tx MXene. ACS Nano 10, 3674–3684 (2016).

-

Ling, Z. et al. Flexible and conductive MXene films and nanocomposites with loftier capacitance. Proc. Natl Acad. Sci. 111, 16676–16681 (2014).

-

Ren, C. East. et al. Accuse- and Size-Selective Ion Sieving Through Ti3C2Tx MXene Membranes. J. Phys. Chem. Lett. 6, 4026–4031 (2015).

-

Guo, J. et al. Theoretical interpretation on lead adsorption behavior of new two-dimensional transition metallic carbides and nitrides. J. Alloy. Compd. 684, 504–509 (2016).

-

Luo, J. et al. Sn4 + Ion Decorated Highly Conductive Ti3C2 MXene: Promising Lithium-Ion Anodes with Enhanced Volumetric Capacity and Circadian Performance. ACS Nano 10, 2491–2499 (2016).

-

Levi, Chiliad. D. et al. Solving the Capacitive Paradox of 2D MXene using Electrochemical Quartz-Crystal Admittance and In Situ Electronic Conductance Measurements. Adv. Energy Mater. 5, 1400815–1401400 (2015).

-

Luo, J. et al. Pillared Structure Design of MXene with Ultralarge Interlayer Spacing for High-Functioning Lithium-Ion Capacitors. ACS Nano xi, 2459–2469 (2017).

-

Wang, R. et al. Graphene-coupled TiiiiC2 MXenes-derived TiO2 mesostructure: promising sodium-ion capacitor anode with fast ion storage and long-term cycling. J. Mater. Chem. A 6, 1017–1027 (2018).

-

Tang, Q., Zhou, Z. & Shen, P. Are MXenes Promising Anode Materials for Li Ion Batteries? Computational Studies on Electronic Properties and Li Storage Capability of Ti3C2 and Ti3C2102 (X = F, OH) Monolayer. J. Am. Chem. Soc. 134, 16909–16916 (2012).

-

Sun, D. et al. Two-Dimensional Ti iii C ii as Anode Fabric for Li-Ion Batteries. Vol. 47 (2014).

-

An, H. et al. Surface-agnostic highly stretchable and bendable conductive MXene multilayers. Science Advances 4 https://doi.org/10.1126/sciadv.aaq0118 (2018).

-

Ghassemi, H. et al. In situ environmental manual electron microscopy study of oxidation of two-dimensional Ti3C2 and formation of carbon-supported TiO2. J. Mater. Chem. A 2, 14339–14343 (2014).

-

Halim, J. et al. X-ray photoelectron spectroscopy of select multi-layered transition metal carbides (MXenes). Appl. Surf. Sci. 362, 406–417 (2016).

-

Maleski, K., Mochalin, Five. N. & Gogotsi, Y. Dispersions of Two-Dimensional Titanium Carbide MXene in Organic Solvents. Chem. Mater. 29, 1632–1640 (2017).

-

Zhang, C. J. et al. Oxidation Stability of Colloidal Ii-Dimensional Titanium Carbides (MXenes). Chem. Mater. 29, 4848–4856 (2017).

-

Ghidiu, M., Lukatskaya, M. R., Zhao, K.-Q., Gogotsi, Y. & Barsoum, Thousand. Westward. Conductive ii-dimensional titanium carbide 'clay' with high volumetric capacitance. Nature 516, 78 (2014).

-

Ju, Y., Wang, M., Wang, Y., Wang, S. & Fu, C. Electric properties of amorphous titanium oxide thin films for bolometric awarding. Adv. Condens. Affair Phys. 2013, v (2013).

-

Marcano, D. C. et al. Improved synthesis of graphene oxide. ACS Nano 4, 4806–4814 (2010).

-

Jung, I., Dikin, D. A., Piner, R. D. & Ruoff, R. South. Tunable Electrical Electrical conductivity of Individual Graphene Oxide Sheets Reduced at "Low" Temperatures. Nano. Lett. 8, 4283–4287 (2008).

-

Romer, F. M. et al. Controlling the conductivity of Ti3Cii MXenes past inductively coupled oxygen and hydrogen plasma treatment and humidity. RSC Adv. 7, 13097–13103 (2017).

-

Ghidiu, 1000. et al. Ion-Exchange and Cation Solvation Reactions in Ti3Ctwo MXene. Chem. Mater. 28, 3507–3514 (2016).

-

Sobolčiak, P. et al. second Ti(iii)C(two)T(x) (MXene)-reinforced polyvinyl alcohol (PVA) nanofibers with enhanced mechanical and electrical properties. PLoS One 12, e0183705 (2017).

-

Hallensleben, M. Fifty. Polyvinyl Compounds, Others. In Ullmann's Encyclopedia of Industrial Chemical science. (Ed.). https://doi.org/x.1002/14356007.a21_743 (2000).

-

Li, R., Zhang, 50., Shi, Fifty. & Wang, P. MXene Ti3C2: An Effective 2D Lite-to-Heat Conversion Cloth. ACS Nano 11, 3752–3759 (2017).

-

Hirakawa, T. & Nosaka, Y. Properties of O2•- and OH• Formed in TiO2 Aqueous Suspensions by Photocatalytic Reaction and the Influence of HiiO2 and Some Ions. Langmuir 18, 3247–3254 (2002).

-

Ghidiu, Chiliad., Lukatskaya, G. R., Zhao, Yard.-Q., Gogotsi, Y. & Barsoum, Yard. W. Conductive 2-dimensional titanium carbide/'clay'/ with high volumetric capacitance. Nature 516, 78–81 (2014).

Acknowledgements

Funding for the study was provided past the US National Science Foundation (Grant No. CMMI-1760859) and TAMU Energy found. We would similar to acknowledge the utilise of the TAMU Materials Characterization Facility and TAMU Microscopy & Imaging Center. We would also similar to acknowledge Dr. Mustafa Akbulut of TAMU for allowing us to use his group's ZetaSizer instrument for zeta potential measurements.

Author information

Affiliations

Contributions

T.H. and Ten.Z. prepared the samples, designed and performed the experiments, and analyzed the data. Due south.S. and Y.C. assisted with the synthesis and etching of Ti3AlC2 MAX stage. W.Due south. assisted with SEM. H.A. assisted with UV–vis measurements of LbL films. J.50.50., Thousand.R., and M.J.Thousand. provided guidance and assisted with the designing of experiments, data analysis, and writing of the manuscript.

Respective authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Boosted information

Publisher's notation: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This commodity is licensed under a Creative Eatables Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give advisable credit to the original author(due south) and the source, provide a link to the Creative Eatables license, and bespeak if changes were made. The images or other third party material in this article are included in the commodity's Creative Commons license, unless indicated otherwise in a credit line to the material. If fabric is not included in the commodity's Creative Eatables license and your intended apply is non permitted by statutory regulation or exceeds the permitted use, y'all volition need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

Reprints and Permissions

Near this article

Cite this article

Habib, T., Zhao, X., Shah, Due south.A. et al. Oxidation stability of TiiiiC2Tx MXene nanosheets in solvents and composite films. npj 2D Mater Appl 3, viii (2019). https://doi.org/10.1038/s41699-019-0089-3

-

Received:

-

Accepted:

-

Published:

-

DOI : https://doi.org/10.1038/s41699-019-0089-3

Farther reading

Source: https://www.nature.com/articles/s41699-019-0089-3?error=cookies_not_supported&code=61eaaae5-f3f7-465a-85b2-336aaf97ec2d

0 Response to "Mxene: a New Family of Promising Hydrogen Storage Medium"

Post a Comment